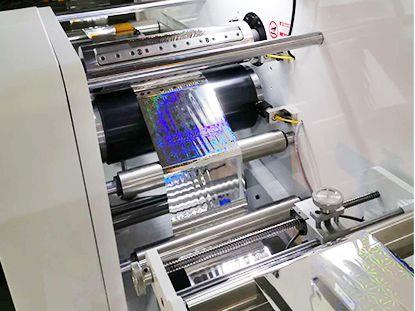

Positioning tracking overprint molding press

Positioning tracking overprint molding pressofFeatures:

Adopt JapanPLCComputer centralized management operation, touch screen control.

Photoelectric control, automatic deviation correction, constant tension winding and unwinding device, automatic temperature control system, stepper motor speed regulation;

Molding accuracy, vertical and horizontal direction by computerPLCcontrol in0.1mmInside;

Full servo motor control, computer control of molding start and end, high molding accuracy, truly equidistant molding;

It is the only one in the country that adopts the principle of electronic cam intermittent type for isometric molding. The moulding method can freely choose two modes. Intermittent and full rotation can be switched freely;

All electrical configuration of this machine adopts well-known brands at home and abroad, and the operation is stable.

Positioning tracking overprint molding pressofThe main technical parameters:

Rewinding and unwinding diameter | Diameter of roll | 100~600mm | Full servo motorServo motor |

Maximum width area | Max pattern area | 250×320mm | |

Computer digital automatic tension systemFull | |||

Automatic constant tension | Constant tension0~25N | ||

automatic tension system | |||

Correction positioning accuracy | Correction | ±0.1mm | CNC stepping systemNC stepping |

precision | correction system | ||

90℃-110℃(Upper roll | |||

Heating temperature | Heat temperature | upper roller)/60℃- | Automatic temperature control (Japan)Auto |

80℃(Lower rolllower | temperature control (Japan) | ||

roller) | |||

Molding speed | Speed of | 2500Version/hour( | Step control, adjustable speedAdjustable |

embossing | pages/h) | stepping control (Japan) | |

Air pressure | Air pressure | 0.5Mpa | |

voltage | Supply voltage | 380V/220V | |

Total power | Total power | 3.5kw | |

Dimensions | Overall size | 2000*800*1200mm | |

|

|

|

|